All Variety of Flanged Pillows - Lovely to Look At - Simple to Sew

Who enjoys sewing in zippers?

Silence…

An occasional cricket chirping….

…..but mostly silence.

Something about zippers frightened an entire generation away from sewing. However, this “zipper anxiety” is totally unnecessary.

Flanged pillows can be completed in less than 2 hours – complete with a frustration-free zipper!

Flanged Pillow with measurements

This tutorial is for an 18″ pillow form. When finished the pillow will have a 2″ flange all the way around – for a total of a 22″ square. (See Math notes at bottom of post if using a different pillow size.)

Materials:

- 28″ of fabric (44″ or wider)

- One 16″ regular zipper

1. Pillow Top = one 24" square

1. Cut the fabric for the pillow back into two rectangles: one 10″ by 24,” and the other 18″ by 24″. The Stash provided some not-really-Ultrasuede for the backs of the pillows

2. Cut one 24″ square for the pillow top. Put aside for later. My daughter choose an upholstery weight checked fabric for her pillow tops. .

3. Find the middle of the length of the zipper and mark with a pin. Just folding the zipper in half does this quite easily (and is Math-Free!)

2. Align mid-point of zipper to mid-point of 24" side of smaller rectangle.

4. Find the middle of the 24″ side of the smaller pillow back rectangle and mark with a pin.

5. Align the middle of zipper to the middle of the rectangle, right sides together. The long edge of the zipper should line up with the edge of the fabric.

3. To avoid "issues" with zipper pull, sew two or three inches with zipper partially opened.

6. Using a zipper foot, sew the zipper to the fabric using approximately 1/4″ seam allowance. The zipper pull will get in the way. To avoid any problem, start sewing with the zipper partially unzipped. Sew about two inches ending with needle down, lift the pressure foot, zip the zipper closed, drop the pressure foot, and continue sewing.

4. Lift pressure foot, close zipper, drop pressure foot, and continue sewing.

Press fabric away from zipper.

5. Aligning zipper for second seam. Fabric is "flapped" to show underlying zipper (just for illustration, please do not flap fabric when sewing the seam). Seam shown with pink dotted line.

Repeat these steps with the larger rectangle and the unsewn edge of the zipper. But do not press this seam.

6. Zipper sewn to both pillow back rectangles.

The zipper will look something like Photo 6.

Take a moment to enjoy your zipper success! Anxiety and frustration free!

Now for the “placket” – kind of an odd word. But then again, so is “flange”.

Lay entire piece flat.

7. Pinch and fold larger rectangle two inches from zipper

Pinch edges of larger rectangle approximately 2″ from zipper as shown in Photo 7.

Create a 2″ fold from the pinches and fold it over the zipper. This will creates the “placket” – or the fold that covers the zipper.

Insert Cardboard and ruler into crease (placket-to-be), then smooth pillow back.

To keep the placket a consistent width, slide a ruler or a piece of cardboard into the crease that was created from the pinch-and-fold. See Photo 8. It should be between 1.5″ and 2″ in depth.

Using your hands, smooth the crease and the pillow back with your hand.

9. "Perfect Depth" Math-Free Measuring Device (perfect for hems as well)

NON-Math Method: Cut a little triangle into the piece of cardboard to define the depth of the crease (placket) as shown in Photo 9. Then use it to make sure the depth is consistent across the entire pillow back. If fractions are preferred – use the ruler instead.

Important: Take care not to pull the crease with too much effort – the zipper must remain flat. Too much effort may pull it over on its side.

Once the depth is consistent, pin the crease (placket) closed at the edges and every 4″ or so. Press with iron.

10. Ovelap seam allowances past end of zipper. The pink dotted line illustrates where the placket seam will be.

Turn the entire piece over so the wrong side is up. Note that the zipper does not extend all the way to the edge of the fabric square. Overlap the fabric in the non-zipper sections and pin – as best as can be done without “deforming” the pillow backs. There will be small sections that do not quite overlap – that is just fine! None of this will show. Everything will be covered by the placket!

Now to define where the placket seam will be – and ensure it is a nice straight seam:

11. Poke pins (hard to see, but are at ends of pink arrows) through pillow back at the zipper seam line of larger rectangle.

Poke pins through the pillow back at the larger rectangle zipper seam. The pins need to be visible on the right side. Just three or four pins are all that is needed.

Turn piece over.

12. Lay a piece of tape along pins to define placket seam line.

The pins that are poking through define the stitching line. Lay a piece of tape (I use painter’s tape) along the pins to create a straight edge for sewing.

13. Tape should be a consistent distance from placket crease.

I do measure the tape to ensure it is the same distance from the placket crease for the entire width. It should be approximately 2″ (approximately!)

14. Sew along edge of tape to create an even, straight placket seam.

Sew along the tape edge as shown in Photo 14. This seam creates a wide flange to hide the zipper.

That little zipper pull may get in the way again. If so, sew to within a few inches of it, unzip it and then continue sewing.

Remove the tape.

15. Completed Placket! Completed Zipper!

For added stability, sew back and forth along the overlapped edges.

The Frustration Free Zipper is complete! (Do a little victory dance!)

Common problem – no worries: If the overlapped sections at the ends of the zipper (Photo 10) were not sewn in place by the Placket Seam, just tack them down with a few hand stitches. They will be secured by the Flange Seam before the pillow is complete.

Place the pillow back flat – right side up. Lay the pillow top on top of it – right side down (right sides together). Pin corners and edges.

16. IMPORTANT: Prior to sewing final seam, the zipper must be unzipped a few inches.

IMPORTANT: Carefully reach through one pinned side and unzip the zipper about 6″ – other wise, turning the finished pillow right side out will present challenges.

17. Sew pillow top and back together 1" from edges.

Sew all the way around, 1″ from edges as shown in Photo 17.

18. Serged edges (optional) and corners trimmed diagonally.

Trim edges to about 1/2″. I serged the edges, but it is not required. Trim the corners diagonally across as shown in Photo 18.

Turn pillow right side out through the unzipped portion of the zipper.

19. Lay pillow top down on ironing board. Use large pin to pull seam while ironing to create flat edge.

Lay the pillow top side down on ironing board. Using a strong pin (a large safety pin works well) pull the seam and iron flat. This creates a nice flat edge, but it does take a while.

Zip the pillow closed.

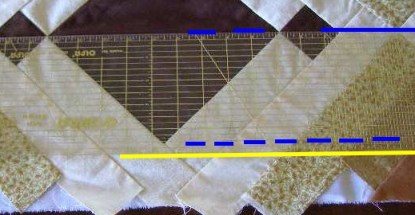

Pin and sew 2" from edge all the way around pillow to create flange.

Pin all the way around the pillow approximately 2″ from edges. Smooth any “fluff” toward the middle of the pillow.

Stitch around pillow 2″ from edge to create that flange! Unzip and fill with an 18″ pillow form!

Completed Flanged Pillow

Pillow is complete!

(Do the victory dance again!)

Math for other pillow and flange sizes.

For pillows with a 2″ flange – add 4″ to pillow form width for pillow top size.

For pillows with a 3″ flange – add 6″ to pillow form width for pillow top size

Two requirements were common themes across every website visited on pattern fitting,

Two requirements were common themes across every website visited on pattern fitting,